Waste normally destined for landfills or older environmentally unfriendly incineration plants can be pretreated to remove recyclable materials such as paper, plastic, glass, cardboard, newsprint, ferrous metal, aluminum and other salable products. Organic fractions can be separated and either partially dehumidified for combustion or converted to fertilizer or other products. The combustible fraction which can include the plastic, paper and other combustibles mentioned above, combined with wood, textiles, tires and other non-recyclables comprise valuable constituents for the production of fuel which is better suited to clean combustion and highly efficient steam and electrical energy production.

Energy may be derived from waste streams generally in the form of a processed or derived fuel which can then be used in various processes to produce steam and therefore, electricity, or chilled water. These products may be sold directly to energy consumers who need fuel to produce their own steam, or in the case of those wishing to produce steam and then utilizing a turbine-generator producing electricity may satisfy their own base electrical demand and introduce the excess directly onto the electrical grid. Steam and chilled water have also historically been used for district heating in large and small cities, universities and smaller communities. Waste converted into energy as described above is an effective energy solution to nearby energy consumers in a cogeneration application.

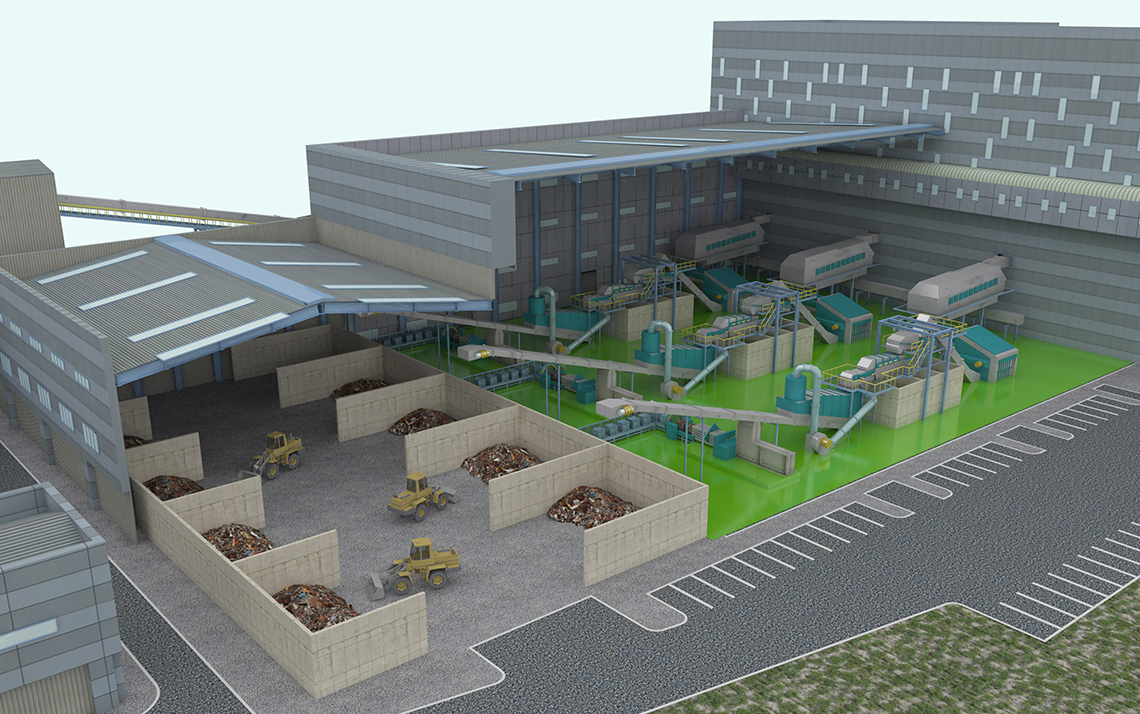

Discover Kogenergy Pretreatment

The flat floor “bunker” is used to move the incoming waste serving several functions: inspection for dangerous items such as fuel tanks, animals, lead-acid batteries and other items to be excluded from the end product; and agitating the waste to slow the fermentation process which produces odor.

After exposure to the flat bunker activity, the waste is then introduced into the pit bunker where claw cranes are used to further agitate and separate the waste further inhibiting fermentation thereby reducing odor and loosening the bulk materials prior to depositing them into the pre-shredding